FAQ

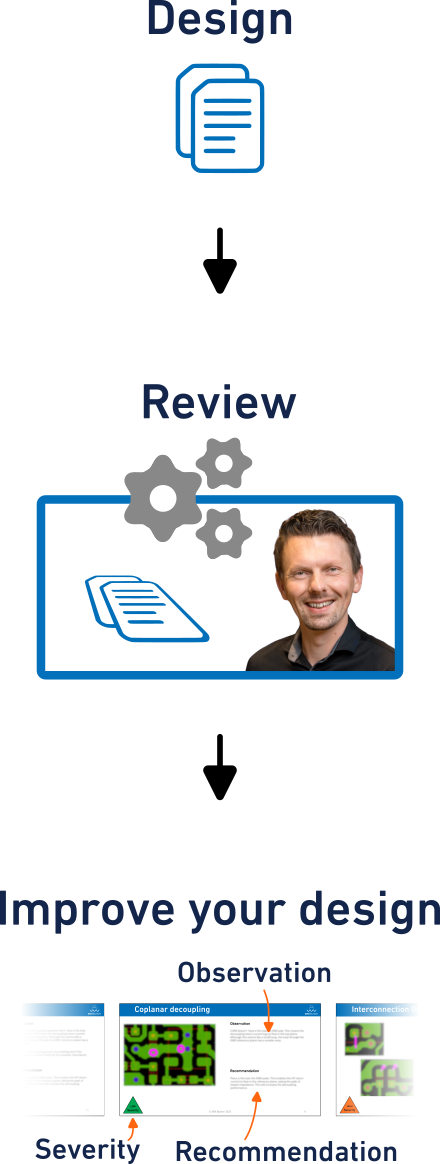

An EMC design review examines your PCB layout and schematic before production to identify electromagnetic interference risks. We find design weaknesses that could cause EMC test failures, so you can fix them before manufacturing.

The ideal time is when your PCB layout is finished but before you order prototypes. This allows you to implement improvements without costly redesigns or production delays.

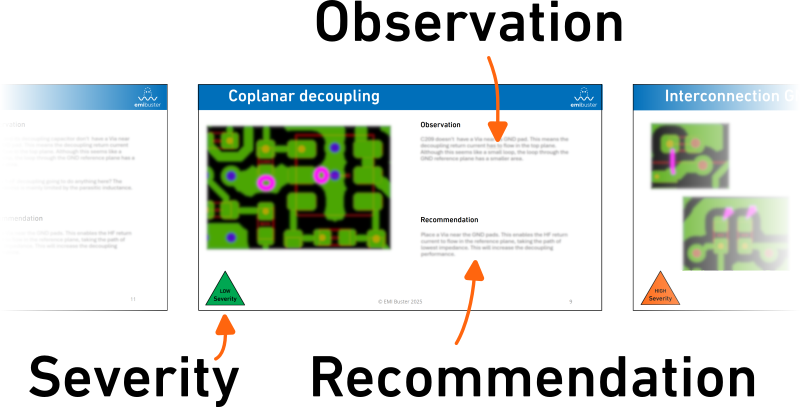

You receive a detailed report with prioritized practical recommendations and explanations to prevent or solve EMC issues. It’s a clear actionable plan to improve the design, including explanation and background info.

Our recommendations target EMI reduction at PCB level, which is the foundation of EMC compliance. Since EMC tests are system-level, we can’t guarantee compliance, but we significantly increase your chances of passing first time.